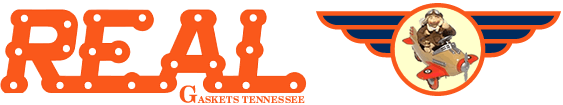

OIL SUMP or OIL PAN GASKET – SILICONE

for

CONTINENTAL ENGINES – IO-346-A; IO-346-B

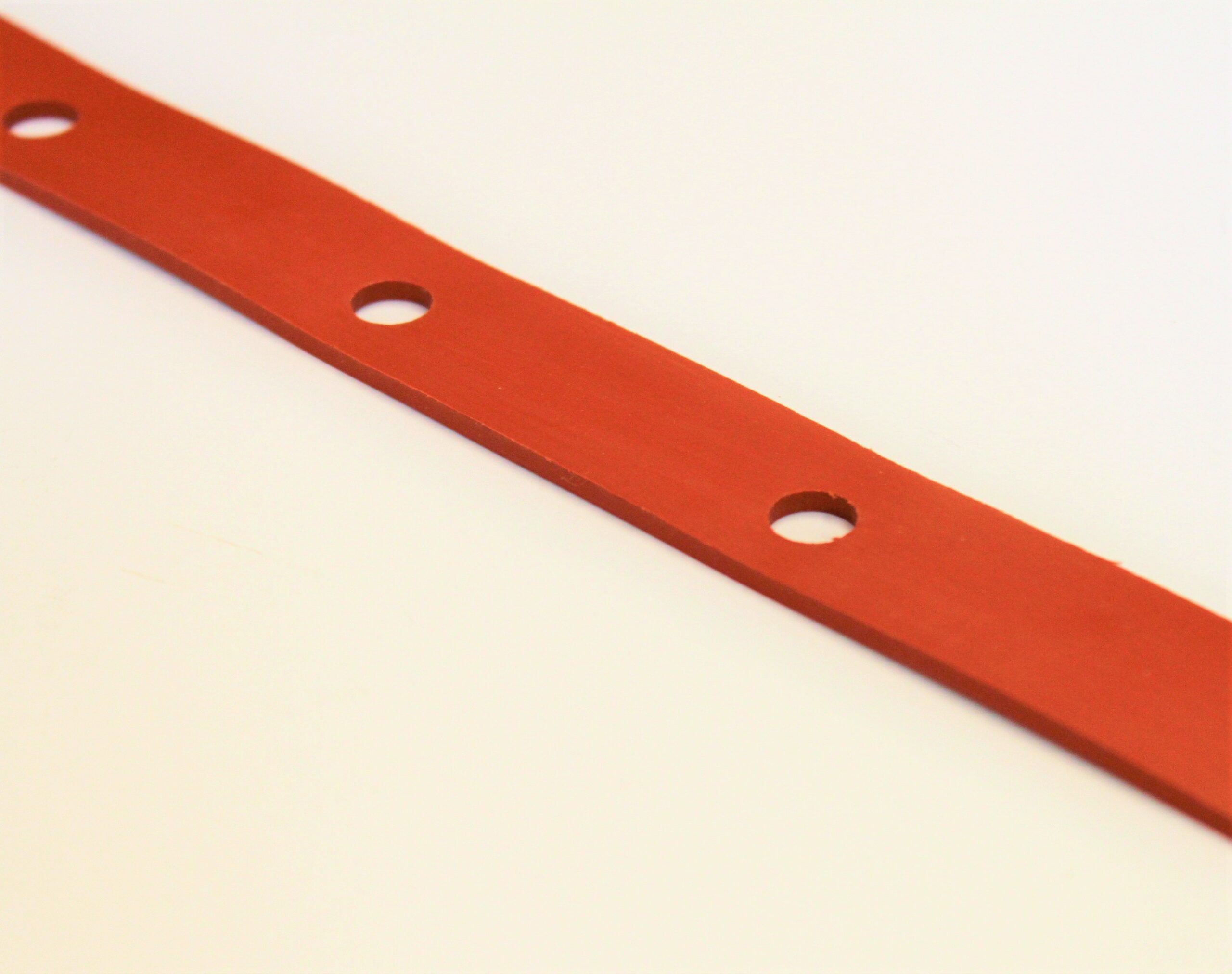

- Our silicone rubber gaskets are made from aerospace mechanical

grade AMS silicone and designed to withstand temperatures

up to 400 degrees Fahrenheit.

- Therefore, they will not break down and deform or crack up

like cork or neoprene.

- Our gaskets seal uneven and warped surfaces, and

eliminates corrosion.

- Gaskets are 100% reusable.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Fits Models: Continental

IO-346-A

IO-346-B

This gasket is not FAA-PMA.

Part #: RG-534915

Oil Sump Gasket or Oil Pan Gasket

Current part #: 652253

Superseded part #: 534915

One gasket

Gasket is 1/8″ thick silicone.

Gasket has 26 bolt holes.

Re-usable.

INSTALLATION AND MAINTENANCE PROCEDURES:

THE GASKET SURFACES MUST BE CLEAN AND DRY.

1. Remove the valve cover and gasket in accordance with the Continental

procedure or in accordance with an acceptable procedure used by the

shop performing the installation.

2. Clean the valve cover and the cylinder surfaces of all residual material.

3. Install gaskets, DRY,

4. Replace the valve cover and torque the cover bolts to 25 in-lbs.

“CAUTION” – DO NOT OVER TIGHTEN.” *

5. Check the cover bolt torque after an engine run up to take off power

or first flight and re-torque the bolts to 20 in-lbs.

6. Check the cover bolt torque annually, and re-torque to 20 in-lbs,

if necessary.

The gaskets are re-usable and the service life of the gasket is

determined by its physical condition on removal.

If the gasket is still pliable and without cracks, tears, or

deterioration, it may be re-used, otherwise discard.

* Over tightening causes the gasket to bulge of squeeze out.

If that happens then back off on the torque.

TO REUSE GASKETS:

Wash gaskets briefly in hot soapy water.

Rinse well and dry all surfaces.

Re-install using the above installation instructions.

PROUDLY MADE IN THE USA.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~